-

SolutionsNOTRE TECHNOLOGIE & NOS SOLUTIONSUne technologie de pointe et des solutions pragmatiques pour une gestion globale de vos contrôles par l'image, pour une réponse spécifique à votre projet et à la mesure de vos besoins.

-

Vision industrielle pour les INDUSTRIELSDes applications dédiées à chaque type de contrôle : Contrôle qualité - Contrôle de conformité - Contrôle de la production et des procédés de fabrication - Contrôle de l'environnement de production...Lire plus

-

Machine vision pour les INTÉGRATEURS & FABRICANTS DE MACHINESNotre expertise en mode collaboratif pour l'intégration de notre technologie dans vos projets d'installation...Lire plus

-

Vision par caméra pour les ENTREPRISES DE SERVICESDes solutions de contrôle par l'image pour vos opérations de maintenance et de gestion déléguée de parcs machines, de réseaux techniques...Lire plus

-

Analyse d'images pour les CENTRES DE RECHERCHEDes algorithmes de pointe pour la détection et le suivi, paramétrables en quelques secondes et utilisés par de nombreux chercheurs et ingénieurs dans de multiples domaines...Lire plus

-

-

Applications métiersAPPLICATIONSDes applications développées sur cahier des charges ou réalisées par vos services de R&D, avec notre accompagnement, grâce à nos solutions logicielles AX Vision et AX R&D.

-

Contrôle d'aspectInspection d'état de surface - Conformité colorimétrique - Profilométrie...Lire plus

-

Tri de piècesClassification par famille de produits, par type de défaut - Appairage...Lire plus

-

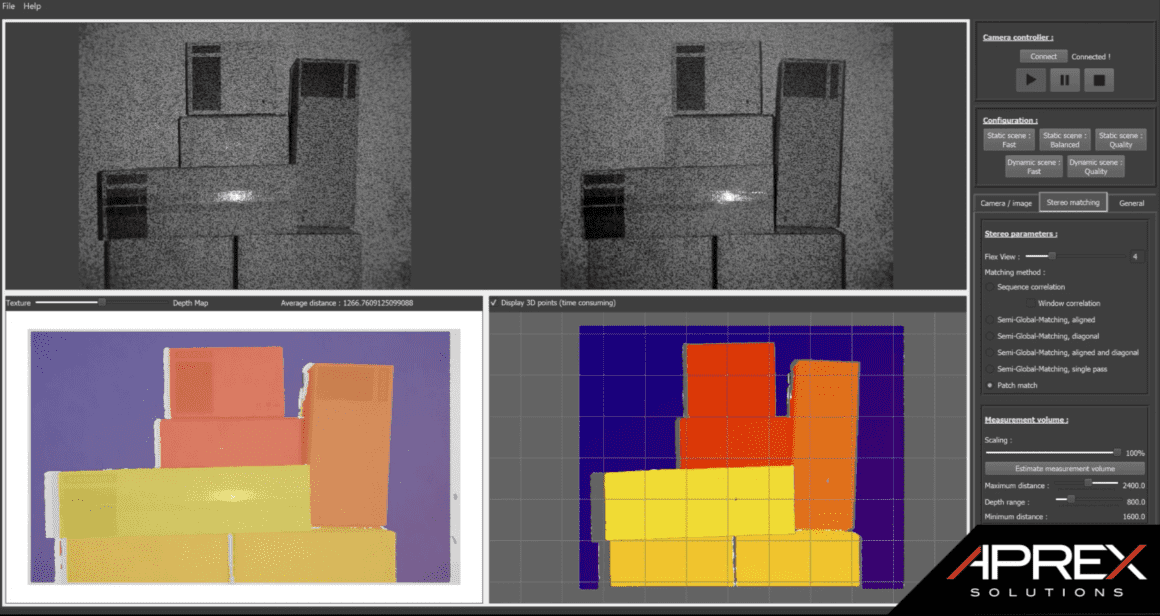

Guidage robotPalettisation / Dépalettisation - Dévracage - Picking - Assemblage...Lire plus

-

Mesure dimensionnelleDiamètre - Distance - Epaisseur - XYZ - LocalisationLire plus

-

Traçabilité industrielle par vision automatiqueDatas des événements de la production et de l'environnement de productionLire plus

-

Vision industrielle pour la logistiquePalettisation / Dépalettisation - Temps de résidence - Lecture OCR Datamatric / QR-codeLire plus

-

Contrôle outils de productionSurveillance des machines-outils avec signalement à l'opérateur et traçabiité des événementsLire plus

-

Lecture de caractères et de codesTraçabilité des produits Conformité par relecture de codes OCR / Datamatrix / QR-codes / DLC...Lire plus

-

-

Secteurs & marchésSECTEURS & MARCHÉSContrôler la qualité et la conformité de la matière première au produit affiné, jusqu'à son emballage. Contrôler et guider la production. Contrôler l'environnement de production. Assurer la traçabilité.

-

AgroalimentaireGranulométrie, forme, texture, colorimétrie, destructuration, lecture DATAMATRIX / QR Code / OCR, vérification des DLC, traçabilité, emballages, détection d'intrants...Lire plus

-

TextileDétection automatique de défaut au défilé : contrôle colorimétrique, contrôle d'aspect, contrôle de motifs, défauts de maille et/ou de filLire plus

-

MétallurgieContrôle de manque/surplus de matière, contrôle dimensionnelle des moules, tri de pièces, défauts de structure...Lire plus

-

MécaniqueDétection de défauts des usinages : dimensionnels, matières, formes, aspects - Gestion par la vision du procédé de fabrication et du parc machineLire plus

-

TréfilerieContrôle des sections de fils, câbles, fibres de verre... - Vérification du tressage multibrins - Contrôle structurel de gaine - Contrôle du bobinage...Lire plus

-

CosmétiqueInspection de défaut pour contrôle de conformité : aspect de surface, texture, matière, colorimétrie, manque ou débordement de matière, positionnement, granulométrie (poudre), fluidité (gel)...Lire plus

-

AutomobileContrôle de pièces (dimensions, manque/surplus de matière, aspect de surface...) - Guidage robot d'assemblage - Traçabilité du process de productions et des piècesLire plus

-

Plasturgie & caoutchoucContrôle de colorimétrie, de manque/surplus de matière, contrôle dimensionnelle des moule, défauts de structure, tri de pièces...Lire plus

-

VerrerieContrôle dimensionnel - Analyse de forme - Conformité de motifs et de dorure - Détection d'inclusion (bulles, filets, corps étrangers...) - Colorimétrie...Lire plus

-

LogistiqueTraçabilité pour le suivi des articles (lecture OCR et Datamatrix) - Vision 3D pour guidage robot de palettisation en vision - Conformité de l'intégrité des emballages...Lire plus

-

Médical & SantéContrôles des dispositifs médicaux, suivi qualité et conformité : prothèse, cathéter, bas de contention, kit biologique, packaging du médicament...Lire plus

-

Recherche & développementAnalyse d'images : microscopie, optique, électronique - Caméra ultra haute vitesse - Tomographie - Sonar...Lire plus

-

-

SolutionsNOTRE TECHNOLOGIE & NOS SOLUTIONSUne technologie de pointe et des solutions pragmatiques pour une gestion globale de vos contrôles par l'image, pour une réponse spécifique à votre projet et à la mesure de vos besoins.

-

Vision industrielle pour les INDUSTRIELSDes applications dédiées à chaque type de contrôle : Contrôle qualité - Contrôle de conformité - Contrôle de la production et des procédés de fabrication - Contrôle de l'environnement de production...Lire plus

-

Machine vision pour les INTÉGRATEURS & FABRICANTS DE MACHINESNotre expertise en mode collaboratif pour l'intégration de notre technologie dans vos projets d'installation...Lire plus

-

Vision par caméra pour les ENTREPRISES DE SERVICESDes solutions de contrôle par l'image pour vos opérations de maintenance et de gestion déléguée de parcs machines, de réseaux techniques...Lire plus

-

Analyse d'images pour les CENTRES DE RECHERCHEDes algorithmes de pointe pour la détection et le suivi, paramétrables en quelques secondes et utilisés par de nombreux chercheurs et ingénieurs dans de multiples domaines...Lire plus

-

-

Applications métiersAPPLICATIONSDes applications développées sur cahier des charges ou réalisées par vos services de R&D, avec notre accompagnement, grâce à nos solutions logicielles AX Vision et AX R&D.

-

Contrôle d'aspectInspection d'état de surface - Conformité colorimétrique - Profilométrie...Lire plus

-

Tri de piècesClassification par famille de produits, par type de défaut - Appairage...Lire plus

-

Guidage robotPalettisation / Dépalettisation - Dévracage - Picking - Assemblage...Lire plus

-

Mesure dimensionnelleDiamètre - Distance - Epaisseur - XYZ - LocalisationLire plus

-

Traçabilité industrielle par vision automatiqueDatas des événements de la production et de l'environnement de productionLire plus

-

Vision industrielle pour la logistiquePalettisation / Dépalettisation - Temps de résidence - Lecture OCR Datamatric / QR-codeLire plus

-

Contrôle outils de productionSurveillance des machines-outils avec signalement à l'opérateur et traçabiité des événementsLire plus

-

Lecture de caractères et de codesTraçabilité des produits Conformité par relecture de codes OCR / Datamatrix / QR-codes / DLC...Lire plus

-

-

Secteurs & marchésSECTEURS & MARCHÉSContrôler la qualité et la conformité de la matière première au produit affiné, jusqu'à son emballage. Contrôler et guider la production. Contrôler l'environnement de production. Assurer la traçabilité.

-

AgroalimentaireGranulométrie, forme, texture, colorimétrie, destructuration, lecture DATAMATRIX / QR Code / OCR, vérification des DLC, traçabilité, emballages, détection d'intrants...Lire plus

-

TextileDétection automatique de défaut au défilé : contrôle colorimétrique, contrôle d'aspect, contrôle de motifs, défauts de maille et/ou de filLire plus

-

MétallurgieContrôle de manque/surplus de matière, contrôle dimensionnelle des moules, tri de pièces, défauts de structure...Lire plus

-

MécaniqueDétection de défauts des usinages : dimensionnels, matières, formes, aspects - Gestion par la vision du procédé de fabrication et du parc machineLire plus

-

TréfilerieContrôle des sections de fils, câbles, fibres de verre... - Vérification du tressage multibrins - Contrôle structurel de gaine - Contrôle du bobinage...Lire plus

-

CosmétiqueInspection de défaut pour contrôle de conformité : aspect de surface, texture, matière, colorimétrie, manque ou débordement de matière, positionnement, granulométrie (poudre), fluidité (gel)...Lire plus

-

AutomobileContrôle de pièces (dimensions, manque/surplus de matière, aspect de surface...) - Guidage robot d'assemblage - Traçabilité du process de productions et des piècesLire plus

-

Plasturgie & caoutchoucContrôle de colorimétrie, de manque/surplus de matière, contrôle dimensionnelle des moule, défauts de structure, tri de pièces...Lire plus

-

VerrerieContrôle dimensionnel - Analyse de forme - Conformité de motifs et de dorure - Détection d'inclusion (bulles, filets, corps étrangers...) - Colorimétrie...Lire plus

-

LogistiqueTraçabilité pour le suivi des articles (lecture OCR et Datamatrix) - Vision 3D pour guidage robot de palettisation en vision - Conformité de l'intégrité des emballages...Lire plus

-

Médical & SantéContrôles des dispositifs médicaux, suivi qualité et conformité : prothèse, cathéter, bas de contention, kit biologique, packaging du médicament...Lire plus

-

Recherche & développementAnalyse d'images : microscopie, optique, électronique - Caméra ultra haute vitesse - Tomographie - Sonar...Lire plus

-

EUROfusion – Sourcing new fusion technologies everywhere in Europe to foster your innovation…

Example of dust monitoring within a tokamak (This video, recorded at 10 000 frames/s, shows dust particles produced by plasma wall interaction

Toolbox for fast detection and tracking of dust particles in tokamaks

Abstract

Monitoring the dust within a tokamak is quite challenging: dust particles in the transitory state measure only few microns and despite their high thermal radiation are quite challenging to be characterized in terms of speed, acceleration and change of direction. For years the plasma physicists of Institut Jean Lamour and then the spin-off APREX Solutions developed measurements tools to carry out truly statistical multi-physics investigations based on the analysis of thousands of tokamak discharges in all kinds of conditions. This solution able to track and analyze images and videos simultaneously and in real is suitable for many non-fusion usecases.

Description of the Technology

DOWNLOAD THE TECHNOLOGY DESCRIPTION

Researchers of the Jean Lamour institute (Lorraine University, France), have developed measurements tools to carry out truly statistical multi-physics investigations based on the analysis of thousands of tokamak discharges in all kinds of conditions.. They decided to found their company to focus on the development of algorithms and software for process monitoring, optimization and securitization .Based on the video tracking software developed to study fusion plasmas (TRACE algorithm), APREX Solutions developed the Track software, that tracks and analyzes images and videos.

Innovation and advantages of the offer

The main benefit of this toolbox is that it can detect and track many objects with very different motion characteristics (difference of velocities, direction changes, sudden accelerations). The ergonomic and intuitive interface allows to analyze any video (Black & White, colored, HD, UHD, from fast imaging camera, infrared camera, microscope, telescope; with any encoding format) and adapt the tool to any situation

Non-fusion Applications

Analyzing multiple objects with very different motion characteristics is a strong painpoint in many industries and research laboratories. In general, all markets and applications requiring a high-performance, reliable vision system (capture, analysis) for parameters tracking, quality control and process understanding could use this technology. It could be for example metal working, automotive, electronics, agrifood, pharmaceuticals, chemicals and fluidics.

EUROfusion Heritage

Monitoring the dust within a tokamak is quite challenging: dust particles in the transitory state measure only few microns and despite their high thermal radiation are quite challenging to be characterized in term of speed, acceleration and change of direction. But the algorithm allowed the monitoring of them. Developed by the plasma physicists of Institut Jean Lamour (which is also EUROfusion Linked Third Party), these plasma monitoring techniques have been successfully used to investigate the generation and transport of dust particles in the ASDEX Upgrade and TEXTOR tokamaks (reference of contracts: EFDA WP12-IPH-A03-2-11/PS-01/CEA & EFDA WP13-IPH-A03-P2-01/CEA/PS), to investigate the dust dynamics in the Pilot-PSI facility (EURATOM-CfP-WP14-ER-01/VR-01 and EURATOM-CfP-WP15-IPH-WPPFC) and finally the properties of plasma filaments in the edge of the COMPASS tokamak (contract EURATOM WP17-ER-CEA-08).