-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

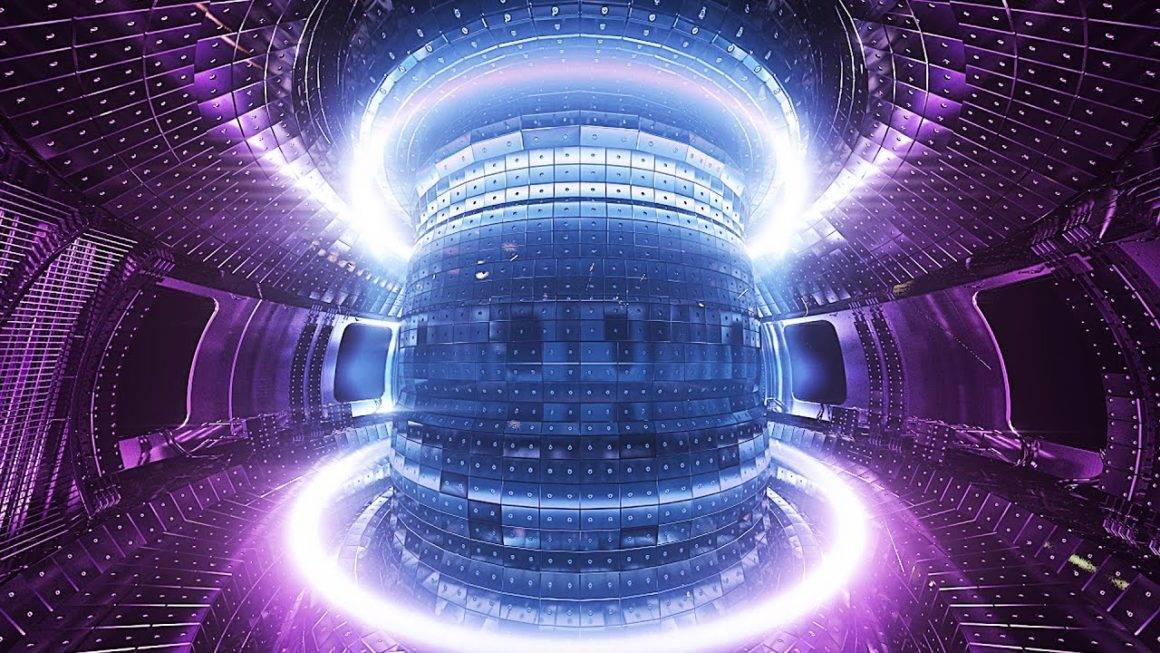

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

APREX Solutions tracks anomalies at the heart of the industry

"Quality control, manufacturing process control, production environment control"

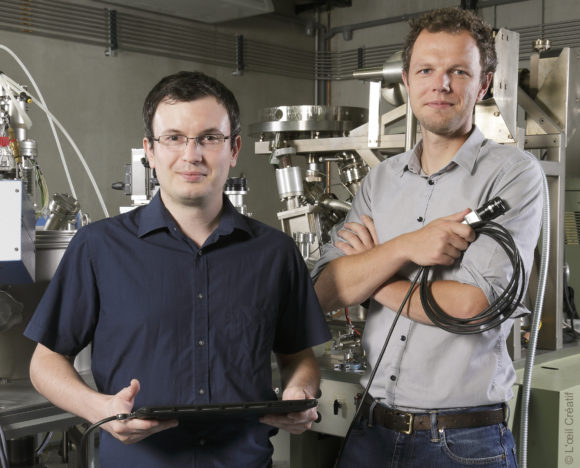

Their software solutions bring intelligence to machines. The young Nancy-based company Aprex has developed in a few years around image translation. Its fine decoding systems are beginning to be used by industry and embedded in robots.

A baby of the Jean-Lamour Institute and the Lorraine incubator, this prolific nursery where genius, public power and nugget researchers mix, Aprex solutions was born in Nancy (54) in 2017 from a collision of gray cells. The company was founded by Romain Baude, PhD in physics and plasma engineering, Mickaël Désécures, a nuclear fusion engineer and PhD in physics, Frédéric Brochard, a researcher at the CNRS and a specialist in rapid imaging, and Jamal Bougdira, a professor at the University of Lorraine's Faculty of Science and Technology. These brilliant minds have developed a software suite capable of making still and moving images speak. Their product, called "Aprex Track" aims to go beyond the current limits of image analysis. It took the team of scientists ten years to develop and consolidate it. Today, the technology is mature and continues to evolve. The company has about ten employees and is really entering the marketing phase. What it offers is expertise - its creators all have experience in image analysis in the nuclear industry - and flexibility. Romain Baude, president of Aprex solutions, details the purpose: "Our software suite allows us to do control, essentially."

Inspect 100 frames per second

Quality control, i.e. ensuring that a product conforms to predefined specifications; manufacturing process control, how parts are assembled, and production environment control for robot guidance, 20, 30 with or without artificial intelligence." Aprex Track thus embeds nuance and insight into machines. "By installing cameras that will inform the robot about the exact conditions of its environment, we bring finesse to the execution of its tasks. We will be able to guide it or enable it to understand certain situations. In logistics, for example, a robot cannot know if a box is right side up or upside down. The camera will therefore be able to tell the robot which way the box is facing and where to put it. Tailored to demand, Aprex's system has other applications. It can detect an air bubble in a material, a roughness on a surface or the absence of tears in plastic parts. Aprex Track can inspect up to 100 images per second. A rate that the eye is unable to keep up with. On the other hand," says Romain Baude, "we at Aprex believe that while the technology is perfect for detecting anomalies, the intervention of an operator is more than relevant for assessing the severity of the problem and making a decision on its resolution." Aprex is keen to keep a heart beating in the chest of Industry 4.0.

Article from l'Est Républicain - Région Lorraine / Saturday 19 June 2021

Author Thierry FEDRIGO / Photo L'Oeil Créatif

Read the article on L'Est Républicain : https://www.estrepublicain.fr/economie/2021/06/19/aprex-solutions-l-analyse-d-images-au-coeur-de-l-industrie