-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

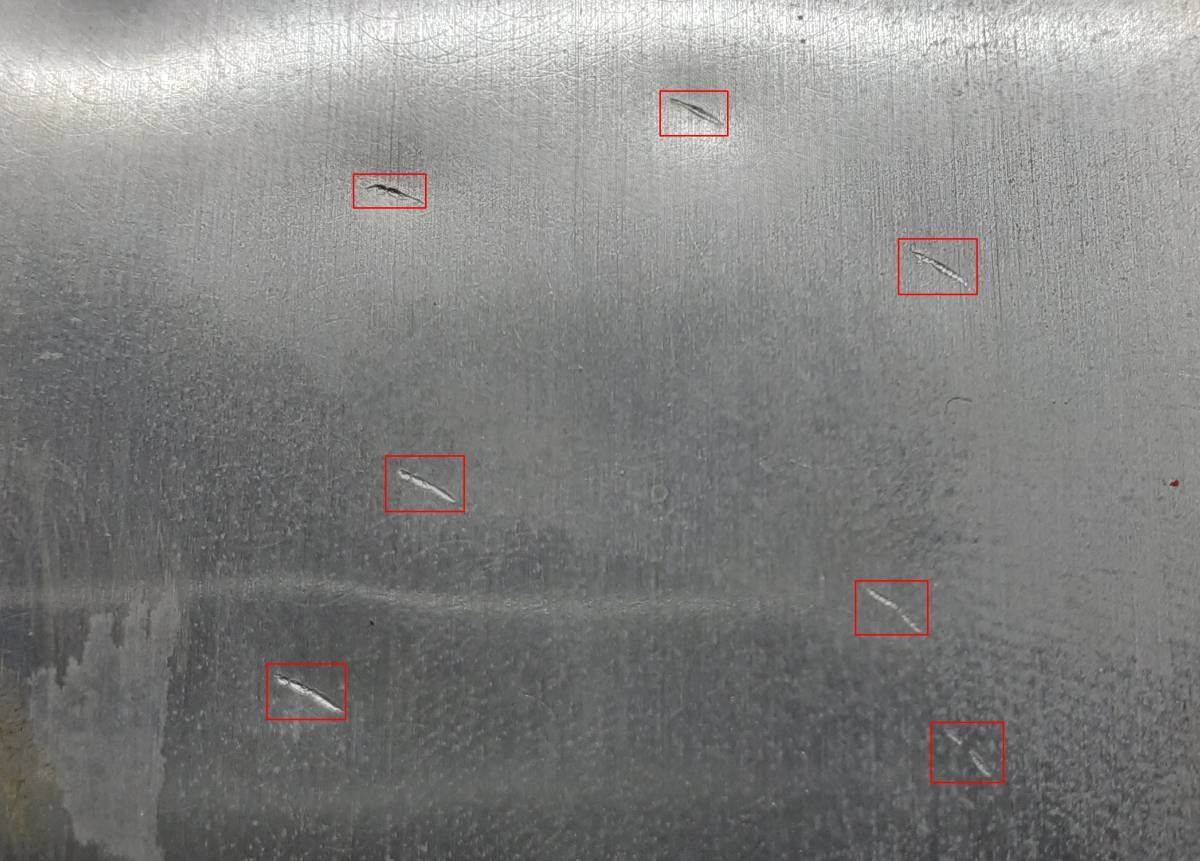

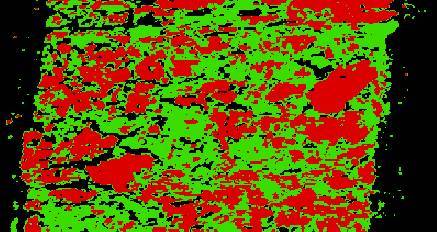

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

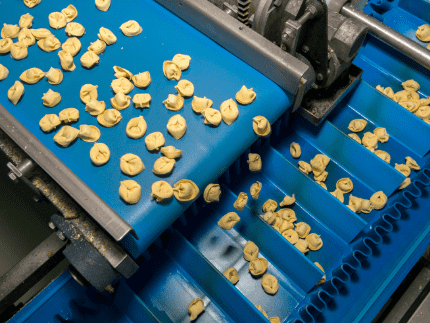

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

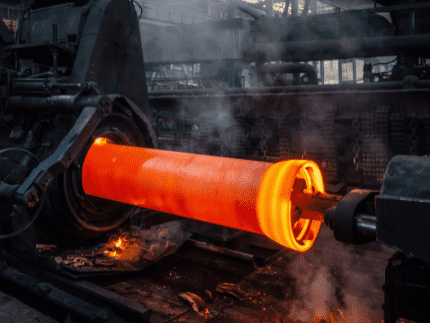

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

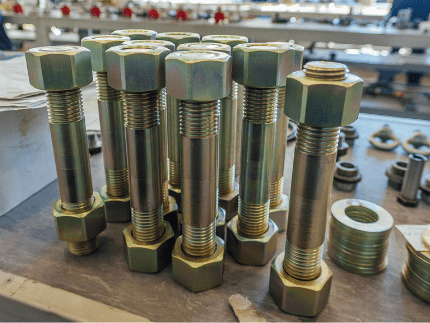

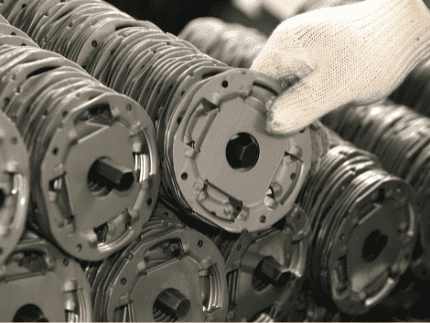

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

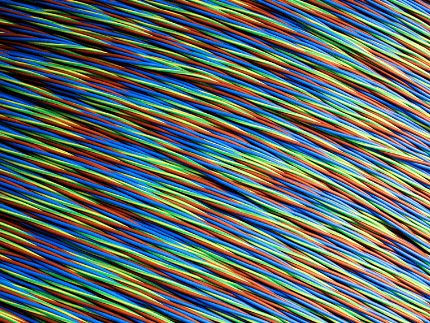

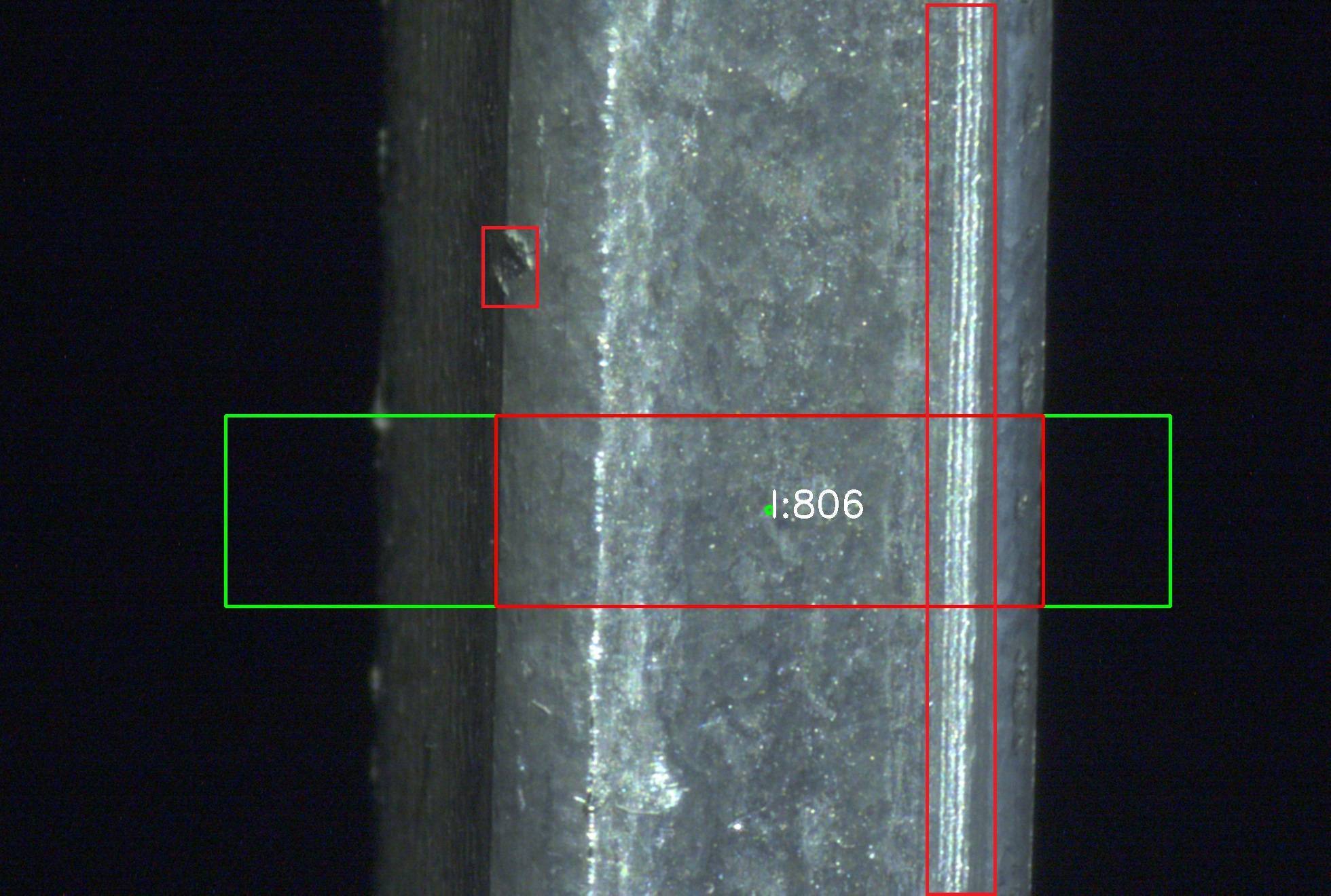

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

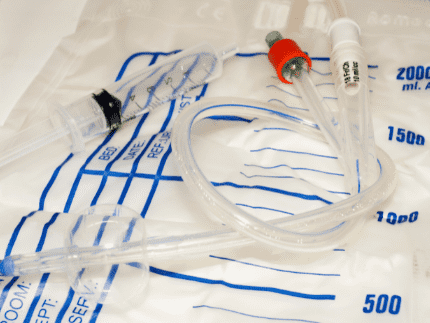

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

Appearance inspection

Appearance inspection

On plastic, metal, wood, glass, composite ...

Page under construction

Des applications de vision industrielle pour répondre aux besoins de contrôles des industries.

Follow our news and receive our use cases