-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

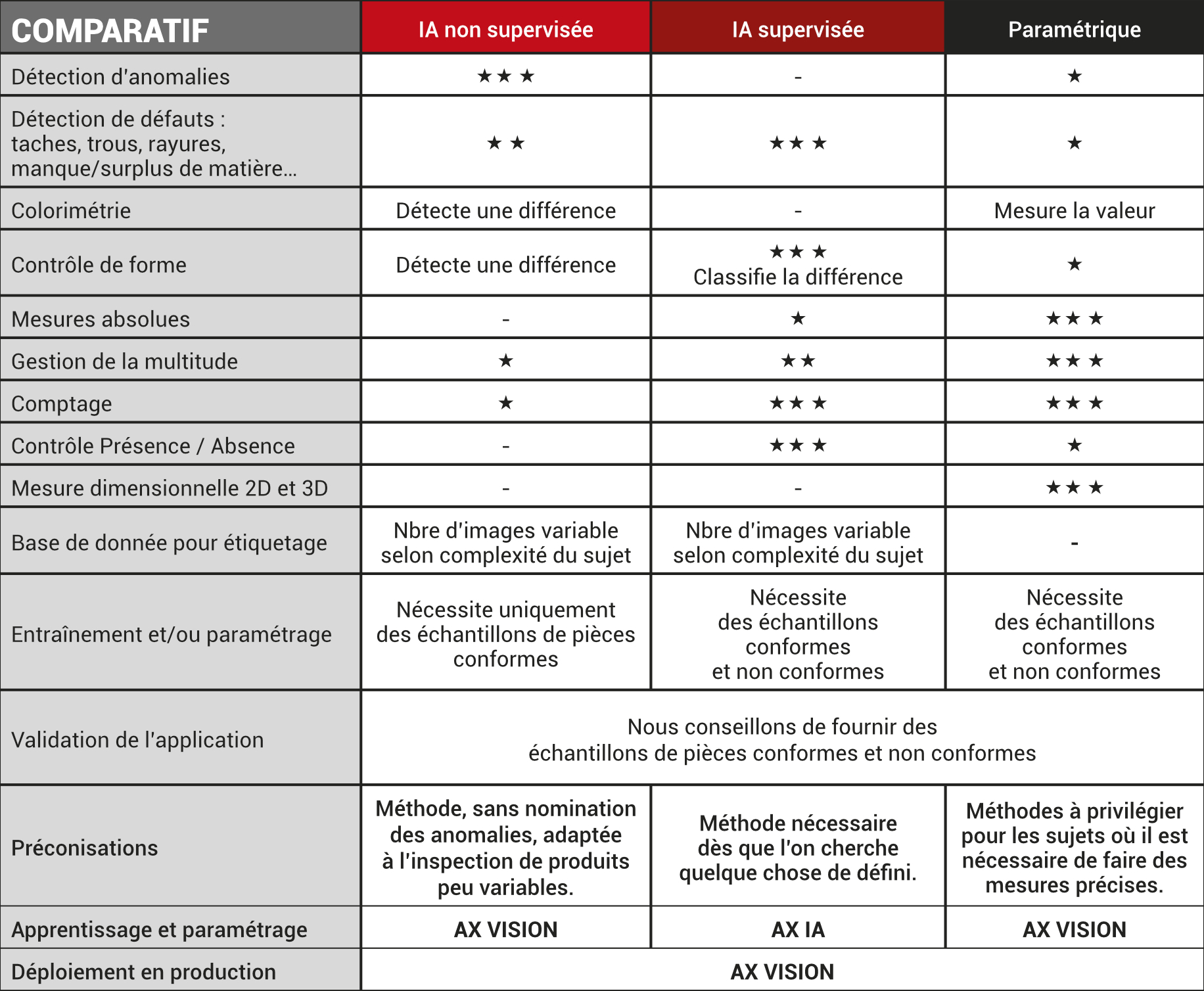

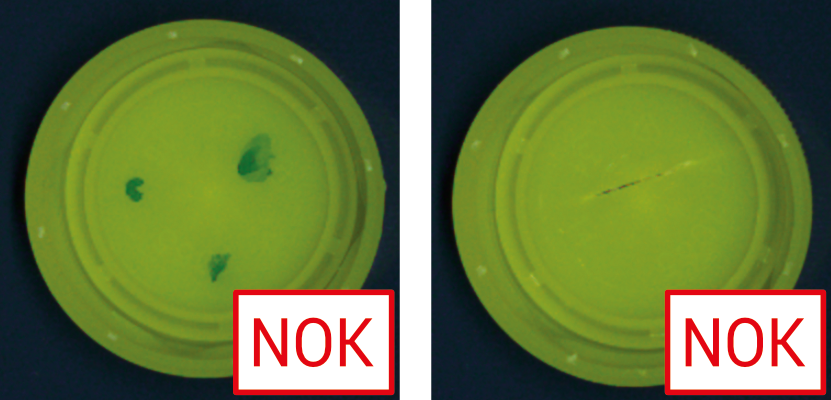

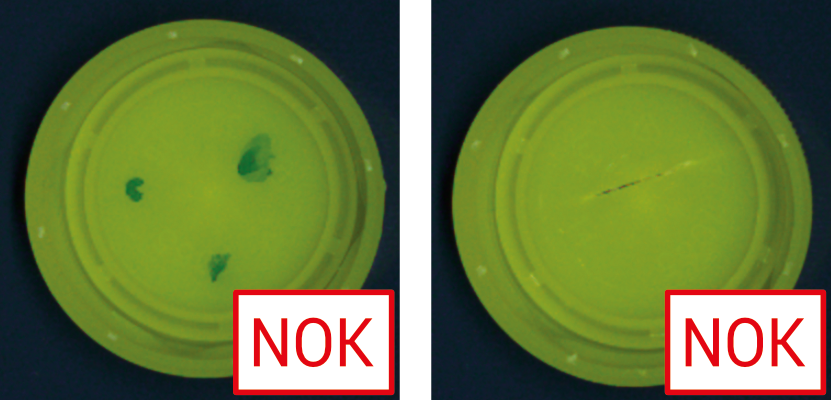

Industrial vision

Tailor-made computer vision technologies, sized for each camera control project

The success of a vision project depends of course on the analysis power of the algorithms, but also and above all on the judicious combination of different technologies.

Whether for applications of : Detection, classification and localization of defects or anomalies - Event detection - Dimensional measurement - Aspect control - Character and code reading... each project has its own specificities: type of defect or process, level of precision and resolution, required conformity thresholds, imperatives related to the tool or the production environment... All these parameters need to be taken into account when drawing up the specifications, in order to be able to dimension an adapted and tailor-made response to each computer vision project.

Thus, while such an application will require parametric methods, for another, it will be necessary to train an artificial intelligence model, and for yet another, to combine several methods.

Our technology, the result of more than 10 years of R&D, embeds the best of the latest generation of algorithmic - parametric and AI (artificial intelligence) technologies. Our AX Vision and AX AI software suites combine different technologies and allow the creation and implementation of customized image processing and optical measurement applications.

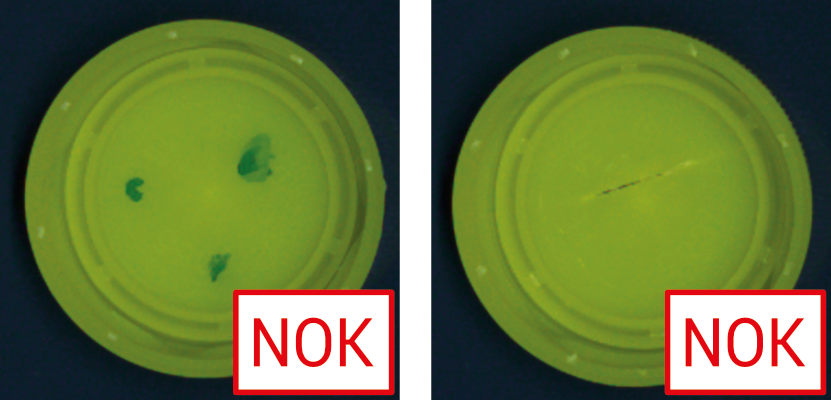

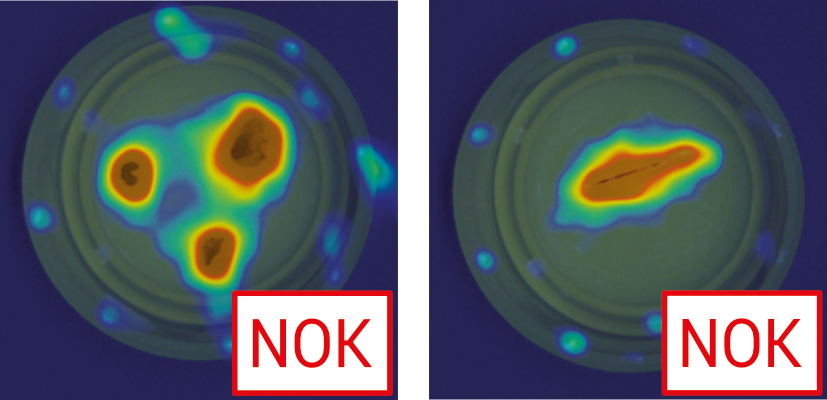

Unsupervised AI anomaly detection method

- How it works: The model is trained, based solely on compliance images. It learns to recognise an OK cap. Any differences with the training images are reported as anomalies.

- Information:

- Allows the approximate location, count and size of an anomaly.

- Does not allow the classification of an anomaly (to recognize it with and name it).

- Required: Compliant parts for learning and some non-compliant samples to validate samples to validate the effectiveness of the application.

- Recommendation: Method adapted to controls for which it is not useful to name the It is not useful to name the anomaly. Method to be preferred for the inspection of products with little variation in a very stable environment.

- Training and deployment in production: AX VISION software suite.

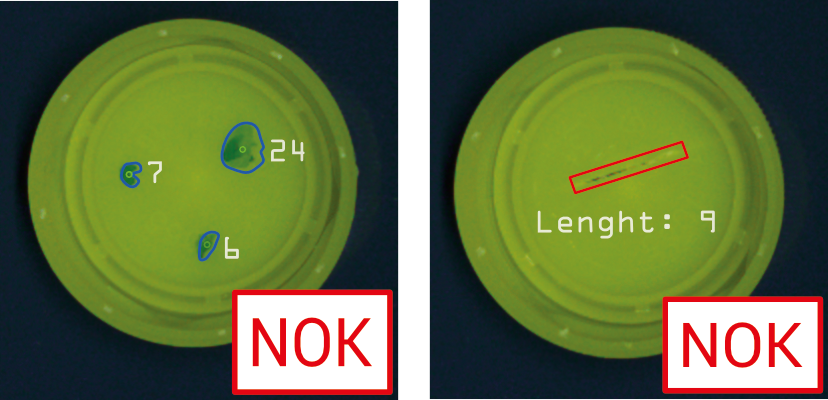

Supervised AI defect detection method

- How it works: The model is trained, based on images of compliance and non-compliance. By labelling the database, it learns to recognise and name specific features. Only trained defects are reported.

- Information:

- Allows the detection, location and classification of the desired characteristics in a very precise and more reliable way: shape, position...

- Allows for precise trimming of defects by Bounding box or by Mask

- Allows to parameterize the conformity thresholding to meet the inspection requirements.

- Does not detect untrained defects.

- Required: A batch of samples containing all the defects to be recognised in production.

- Recommendation: A method that is necessary when trying to detect something defined with a high degree of accuracy.

- Training: AX IA software suite.

- Deployment in production: AX VISION software suite.

Defect detection method Parametric

- How it works: Algorithms parameterised and calibrated according to a threshold of

defined by the specifications.

Only out-of-tolerance measurements are reported as NOK - Information:

- Allows dimensional measurements (micron, mm, m) and colorimetric measurements (LAB, HSV, RGB) with precision, in absolute values.

- Allows multiple inspections to be managed, even at very high speeds.

- Does not allow the classification of a defect, nor work on cases that have not been that have not been parameterised.

- Required: A batch of samples of non-conforming parts with indication of the value of the defects.

- Recommendation: Preferable method for dimensional and colorimetric measurements.

- Parameterisation and deployment in production: AX VISION software suite.