-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

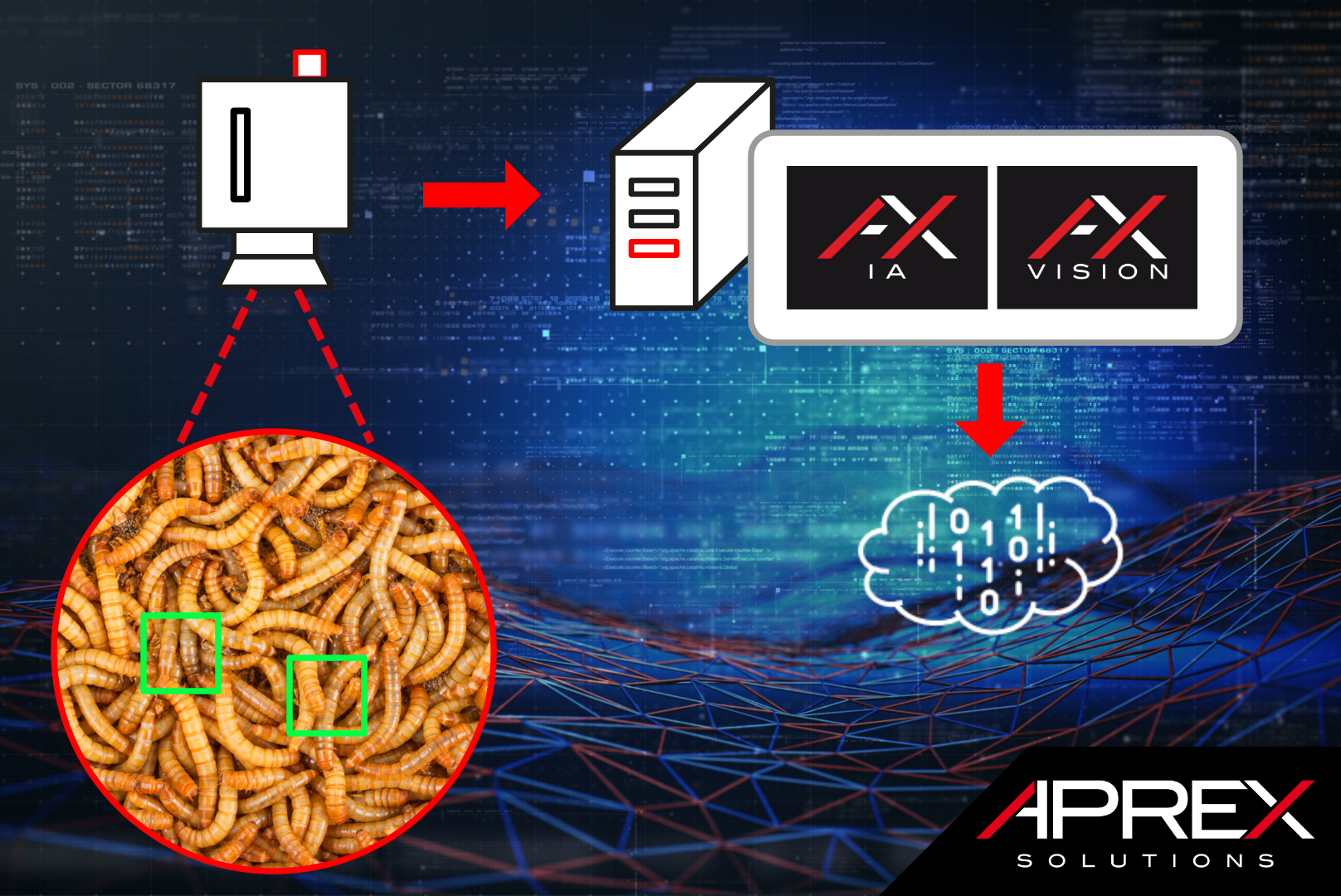

APREX Solutions brings its expertise in machine vision to the R&D projects of Ÿnsect, a major player in Agritech.

Ÿnsect, a world leader in the production of insect protein for animal and human consumption, has chosen APREX Solutions' expertise to support them in the R&D of the Ÿnfabre project. APREX's camera image analysis solutions help select the best mealworm strains to optimize production quality.

The production of insects as a response to the challenges of a new alternative and sustainable source of food protein is a completely new market. Its development required a major research phase for Ÿnsect with an R&D program in two parts on the study of insects: genotyping (study of genes) and phenotyping* (physical characteristics). APREX Solutions was entrusted with the latter operation.

Observe and characterize, to identify champions

Insect phenotyping consists of analyzing each individual, in real time and continuously, to determine physical and anatomical characteristics, such as size and color.

The observations are made using state-of-the-art algorithms that combine the best of conventional vision methods and artificial intelligence.

The data collected, thanks to APREX Solutions' software suites - AX Vision and AX AI - are fed into a database whose objective is to select the insect strains that will combine the best performance criteria.

The first results of this research are expected within four years. Ÿnsect has announced the launch of its first breeding unit in France by 2026. Each unit will have the capacity to supply five farms with reproductive insects for an increased productivity of more than 15% in the first year. (source Maddyness)

Ÿnsect and APREX, a confirmed partnership

Since 2019, APREX Solutions has been supporting Ÿnsect production control projects, particularly on the Ÿnfarm vertical factory project, intended for the breeding and production of mealworms.

You can imagine the context: hundreds of tanks containing several thousand insects to be analyzed in a continuous process with several controls to be carried out at the same time. In concrete terms, this represents 936 million pixels to be analyzed in 12 seconds for more than 6 KPI measured in parallel. Knowing that this time period includes: capture, analysis, restitution of results, it is very fast!

APREX Solutions' technology and pragmatism made the difference

APREX Solutions' software solutions are based on algorithms resulting from over 10 years of R&D. They combine the best of conventional camera-based image analysis methods and state-of-the-art artificial intelligence (AI). This technology and APREX Solutions' expertise in combining vision, algorithmic optimization, AI, and photonic optics over a wide spectral range has allowed to push information beyond the visible range.

However, any vision system, no matter how efficient it is at the feasibility study stage, must then be tested in the field. It must be able to be integrated into the production system, taking into account the constraints: production techniques, industrial environment, and interactions with the HMI operators (human-machine interfaces).

In this sense, APREX Solutions' solid experience in the field applied to quality control and manufacturing processes in various industrial fields, such as food processing, metallurgy, plastics, glass, textiles and mechanics, was a determining factor in the choice of Ÿnsect.

They were able to rely on APREX Solutions' approach, which claims to be transversal and pragmatic, with end-to-end project support: a tailor-made and à la carte service, from specifications to operational maintenance, including feasibility studies, prototyping, integration and implementation on site.

"We claim a human, pragmatic and efficient approach and we rely on a network of reliable partners (equipment suppliers, integrators...) to accompany our customers' projects from A to Z: from the identification of the need, to the implementation of the vision system on the production line, without forgetting the training until the desired level of autonomy.

Our objective is to contribute to the transition of companies to Industry 4.0 for a better rationalization and increased security of their production.

Our ambition is to provide them with the simplest, most advanced and easiest to use solution and to position ourselves as a reference in the machine vision market,"

says Romain BAUDE, CEO of APREX Solutions.

*This study completes the high-throughput sequencing and genotyping performed by CEA-Genoscope and Thermo Fisher Scientific.

Read the article published on Maddyness:

"Ÿnsect adds beetle genetic analysis to its bow"