-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

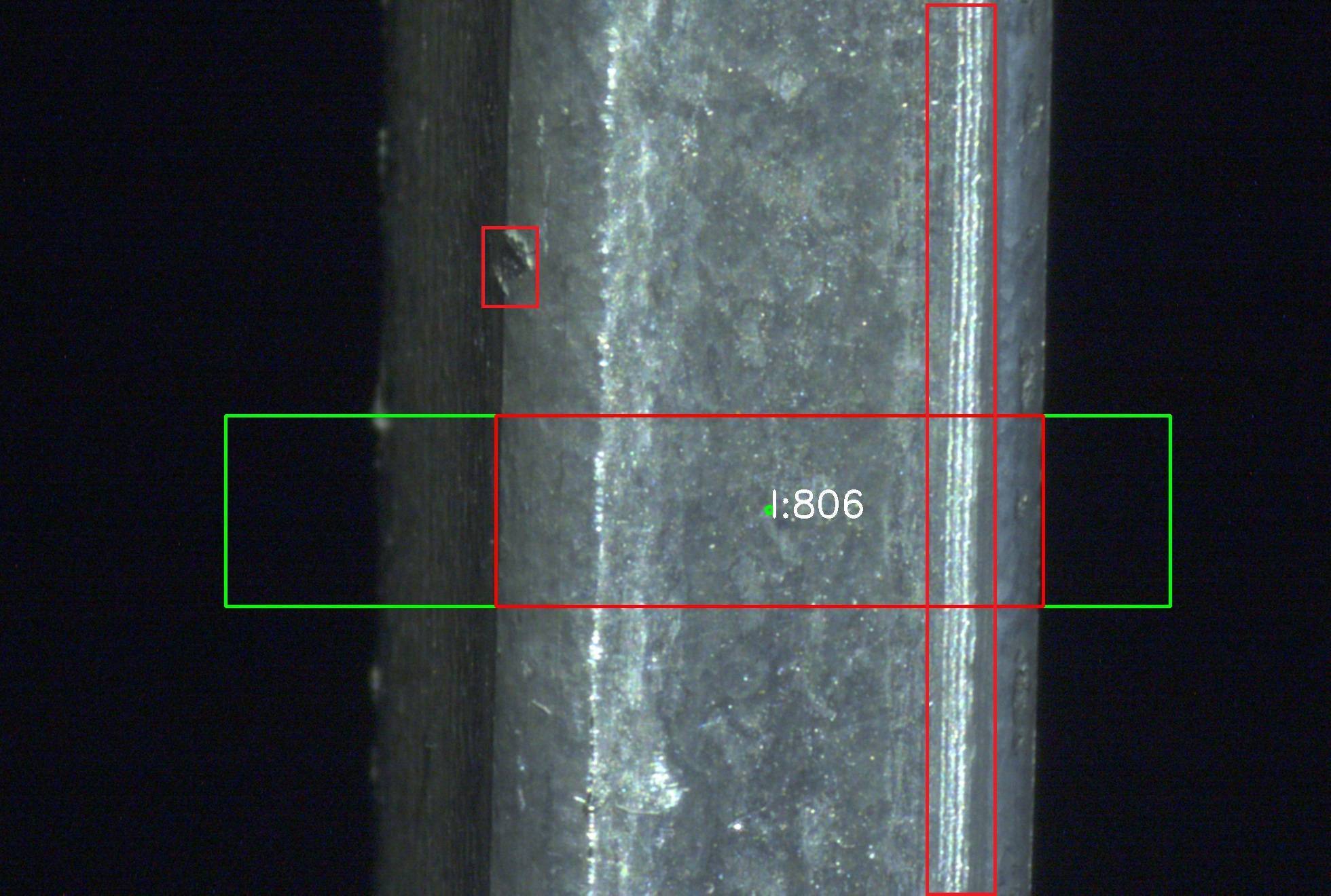

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

-

SolutionsOUR TECHNOLGY & OUR SOLUTIONSState-of-the-art technology and pragmatic solutions for a global management of your controls by image, for a specific response to your project and to the extent of your needs.

-

Machine vision for MANUFACTURERSApplications dedicated to each type of control: Quality control - Compliance control - Production and manufacturing process control - Production environment controlLire plus

-

Machine vision or INTEGRATORS & MACHINES MANUFACTURERSOur expertise in collaborative mode for the integration of our technology in your installation projects.Lire plus

-

Camera based-vision for SERVICE COMPANIESImage control solutions for your maintenance operations and delegated management of machine parks, technical networks, etc.Lire plus

-

Image Analysis for RESEARCH CENTERSState-of-the-art detection and tracking algorithms that can be configured in seconds and are used by many researchers and engineers in multiple fields.Lire plus

-

-

ApplicationsAPPLICATIONSApplications developed to specifications or by your R&D departments, with our support, thanks to our AX Vision and AX R&D software solutions.

-

Appearance inspectionSurface finish inspection - Colorimetric - Compliance - Profilometry ...Lire plus

-

Parts sortingClassification by product family, by type of defect - PairingLire plus

-

Robot guidancePalletizing / Depalletizing - Unpicking - Picking - Assembly...Lire plus

-

Dimensional measurementDiameter - Distance - Thickness - XYZ - LocationLire plus

-

TracabilityProduction and production environment event dataLire plus

-

LogisticPalletizing / De-palletizing - Residence time - OCR Datamatric / QR-code readingLire plus

-

Tool breakage detectionMonitoring of machine tools with reporting to the operator and traceability of eventsLire plus

-

OCR / Datamatrix / QR-codes readingProduct traceability Compliance by OCR / Datamatrix / QR-codes / DLC reading...Lire plus

-

-

Fields & marketsFIELDS & MARKETSTo control the quality and conformity of the raw material to the refined product, until its packaging. To control and guide the production. To control the production environment. To ensure traceability.

-

Agri-foodGranulometry, shape, texture, colorimetry, destructuring, DATAMATRIX / QR Code / OCR reading, verification of use-by dates, traceability, packaging, input detection.......Lire plus

-

TextileAutomatic detection of defects on the run: colorimetric control, aspect control, pattern control, stitch and/or yarn defectsLire plus

-

MetallurgyControl of lack/overflow of material, dimensional control of molds, sorting of parts, structural defects...Lire plus

-

MechanicalDetection of machining defects: dimensions, materials, shapes, aspects - Management by the vision of the manufacturing process and the machine parkLire plus

-

Wire drawingControl of wire sections, cable, glass fiber... - Verification of multi-strand braiding - Structural control of sheaths - Control of winding...Lire plus

-

cosmeticsDefect inspection for compliance control: surface aspect, texture, material, colorimetry, lack or overflow of material, positioning, granulometry (powder), fluidity (gel), etc.Lire plus

-

AutomotiveControl of parts (dimensions, lack/overflow of material, surface aspect...) - Assembly robot guidance - Traceability of production process and partsLire plus

-

Plasturgy & rubberControl of colorimetry, lack/overflow of material, dimensional control of molds, structural defects, sorting of parts...Lire plus

-

GlassDimensional control - Shape analysis - Pattern and gilding conformity - Inclusion detection (bubbles, threads, foreign bodies...) - Colorimetry...Lire plus

-

LogisticTraceability for article tracking (OCR and Datamatrix reading) - 3D vision for palletizing robot guidance - Packaging integrity compliance...Lire plus

-

Medical & HealthMedical device controls, quality and compliance monitoring: prosthesis, catheter, support stockings, biological kit, drug packaging, etc.Lire plus

-

Research & DevelopmentImage analysis: microscopy, optics, electronics - Ultra high speed camera - Tomography - Sonar...Lire plus

-

Solocap / Aprex Track IA : case study of a quality control in plastics processing

Focus on cap control at Solocap

Detecting tears and micro-tears on plastic caps of 40 different colors and shades, and running at high speed on a production line, such was the quality control objective, aimed by the company SOLOCAP Mab (1).

APREX Solutions has successfully met this objective.

SOLOCAP, on its Contrexéville industrial site, produces all types of plastic closures for the food sector, in particular a top-of-the-range screw cap, suitable for all glass or PET bottles.

Thanks to a ring of wings that can be clipped around the neck of the bottle, this cap allows an easy, quick, completely tight and secure crimping.

For this purpose, the fins must be systematically and reliably checked for cracks, tears and torsion during production, at a sustained rate.

Since the old system did not meet the new requirements, it was necessary to modernize the inspection process.

A concerted set of specifications

The specifications were developed in conjunction with the SOLOCAP team and we deployed our solution in two stages:

First, with our APREX Track IA solution, we created the specific application "bouchon-Solocap". This application interweaves different object detector, classifier and standard methods working at different scales to deliver a final compliance result.

That is to say, nearly 5 levels of controls, with multiple control points, which allow to reach a reliability rate on the result, higher than 99,99%.

In a second step, we implemented this application on the production line with APREX Track C&M. This allows to control its execution by linking an IDS Imaging(2) UI 3280 CP HQ camera, an Effiring efflux lighting and an industrial automaton. This also allows to record, in real time, the traceability data.

The excellent color rendering and 5.01 MP resolution with a frame rate of 26 fps allowed us to complete this project quickly.

Without requiring any specific development other than a quick training of the AI methods, the APREX TRACK software suite allowed us to obtain an efficient and scalable result, with ease.

Crossed testimonies

Romain Baude - Founder of APREX solutions

"The difficulty of this project lies above all in the very tenuous nature of the defects sought and in the multitude of colors. With our software suite it was possible to set up a vision application quickly. Despite its complexity."

Anthony Vastel - Technical and Industrial Director of SOLOCAP

"APREX's approach and their AI-based solution have opened new doors for our 100% vision control. Our requirements in terms of product security but also in terms of control of rejects and especially false positives were quickly met thanks to a dynamic team that listens to us. We are convinced that we can go even further by improving the efficiency of the system at SOLOCAP and by applying it to other production lines.

(1) SOLOCAP, located in Contrexéville, is a subsidiary of La Maison Mélan Moutet, "taste conditioner since 1880", a French family business specialized in the manufacture of closures for food packaging.

IDS Imaging, located in Germany, is one of the main players specialized in industrial cameras.